HIGH PRESSURE MARINE LOADING ARMS

The loading and unloading of petrochemicals, oil products and liquefied gases at a tanker berth can be dangerous and hazardous. In addition, jetty personnel and ship’s crews are often under pressure to minimise tanker berth turnaround of time, whilst constantly addressing the numerous safety issues concerning their ship, the jetty installation, the environment and personnel.

This is where MIB products play a key role in such operations; providing speedy connection and disconnection of the jetty marine arms or flexible hoses, emergency safety release systems and a range of associated products to enhance the performance of these activities.

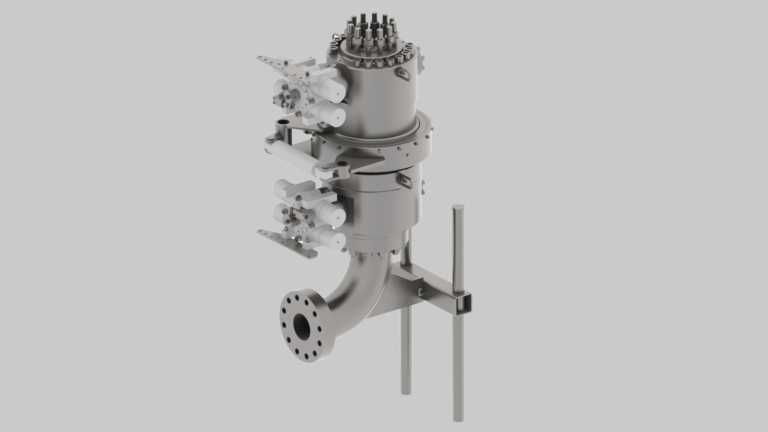

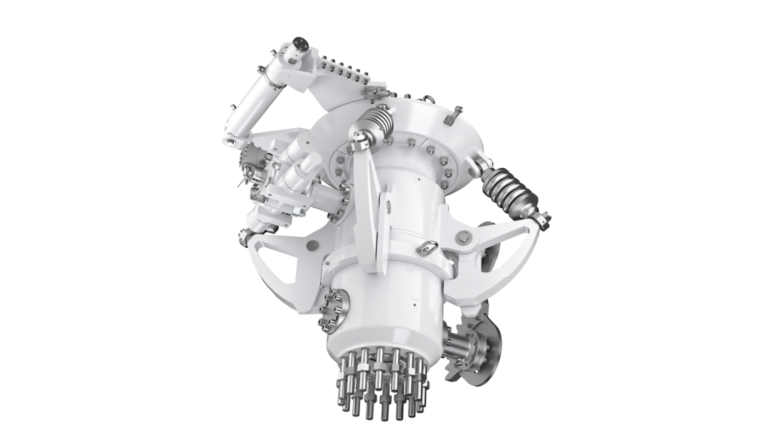

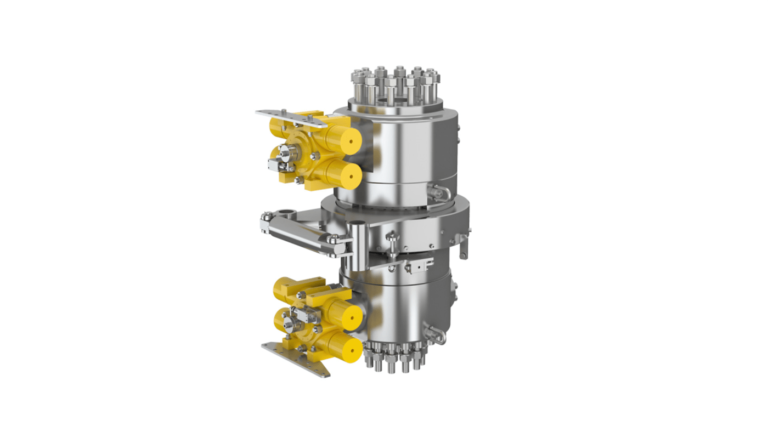

Specifically for High Pressure Natural Gas offloading application from Floating Storage Regassification Units (FSRU), MIB developed a purpose-designed High Pressure Emergency Disconnect System (EDS) made of MIB integrated DBV/QCDC system, to be installed in the vertical of the outboard end of the Marine Loading Arms. Typically such application does not require frequent connection/disconnection operations of the MLA to/from the FSRU vessel, therefore there is no real need for a dedicated QCDC in most cases. Our Integrated EDS provides security of the installation, the crews and environment under emergency situations, in particular offering a minimum amount of trapped HPNG between the closed EDS valves to blow down during the emergency release sequence.

Alternatively, MIB can offer high pressure separated ERS and QCDC in case of conventional set-up requested by the Customer.